Volvo Group - Improving Supply Network Transparency

Graduate Project aimed at improving the supply chain transparency by enhancing communication between suppliers and Volvo. The need for supply chain transparency is largely due to regulatory requirements on sourcing, meaning a system to track and follow parts around the earth needed to be developed.

Introduction

Volvo Group

The Volvo Group, headquartered in Gothenburg, Sweden, is a leading company in the transportation and commercial vehicle industry. Volvo Group Digital & IT serves as an internal consultancy supporting all other departments. My role in this was to be part of the user research and design process. Developing interactive prototypes that display ideal user flows based on the user requirements. This system is used by 10 000s of suppliers and supplies 100 000s of parts to Volvo yearly.

Tackling the problem

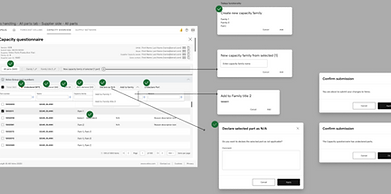

The existing system required significant improvements to streamline supplier reporting processes. Key challenges included excessive clicks, lengthy learning curves, and time-consuming report filling. In addition to that, there are also many missing features that are requested by users, such as multi-select, local filters, search functions, etc. that continually come up in the user interaction process.

Using this we decided to create several changes to the designs, we made a more uniform Volvo Design using the Volvo Design System with colors, fonts, and design patters. We created local filter functions to improve sorting and finding factory parts, icons on buttons, and added more blank space (white space) to make it easier to navigate.

To improve the usability we worked continually with user representatives that had deep insight the average users, in order to create user tasks and descriptions for what should be our key priorities when designing and what the needs are. Then we would develop the designs and allow them to chose between 2 options. This process would continually be done in collaboration with programmers to find, fix and prevent issues.

Outcome

Volvo Group suppliers can expect to benefit from both efficiency gains and an improved user experience. Efficiency gains include a 33% reduction in learning time, a 20% decrease in form filling time, and simplified processes for over 50,000 suppliers. Additionally, an enhanced user experience is provided through intuitive search and filter functions that align with Volvo Design System standards.